What is Swiss-type lathe machining?

Swiss-type lathe machining is a subtractive manufacturing process that uses

multi-faceted cutting tools to machine a single piece of material, effectively performing multiple

turning and milling operations in a single pass.

Typically, Swiss-type lathe-machined parts and components are very small. Originally developed for

manufacturing parts for Swiss watches, this technology has been continuously improved over time for

producing parts and equipment for a wide range of applications.

Our machining technology offers exceptional precision, with micro-machining accuracy down to 1-4

micrometers. With decades of experience producing high-precision, finely machined parts for numerous

industries, the HLH Industry team is able to manufacture complex parts and components that meet the most

demanding specifications.

Applications of Swiss-type lathes

Swiss-type lathes have a wide range of applications and are an ideal choice for manufacturing parts in many industries.

watchmaking industry

Swiss-type machining was originally developed for the watchmaking industry to manufacture miniature, high-precision mechanical parts.

Aerospace

The aerospace industry requires lightweight, high-precision components with extremely tight tolerances during assembly. Swiss machine tools, renowned for machining small, complex parts, are ideally suited for this purpose.

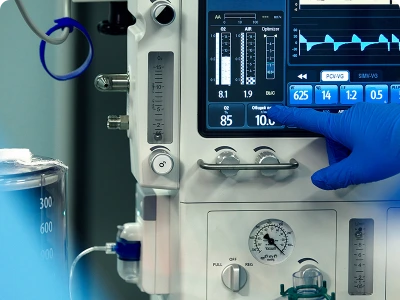

Medical devices

Swiss-type lathes have greatly met the high standards of the medical field in terms of their ability to manufacture medical devices, surgical screws, and implants.

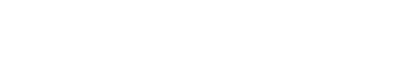

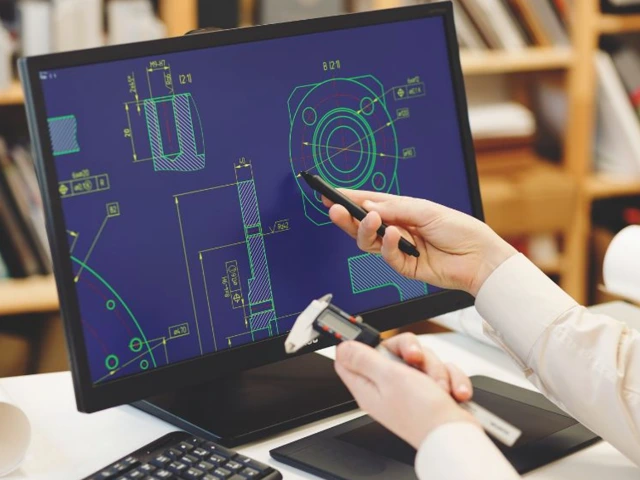

Working principle of Swiss-type lathe machining

What is the working principle of a Swiss-type lathe?

A Swiss-type lathe uses a sliding spindle mechanism. The workpiece moves along the Z-axis via a guide

bushing, while the cutting tool remains stationary. This structure minimizes the distance between the

tool and the workpiece, improves stability, and allows for simultaneous machining on multiple axes.

Key motion elements:

1. The sliding spindle head moves the bar stock axially.

2. The guide bushing supports the bar stock in a position very close to the cutting tool.

3. Multiple tool holders allow for transverse, longitudinal, and vertical machining in a single setup.

Our advantages in Swiss-type lathe machining

Get a Quote

Please place file(s) for transfer in the same folder and ZIP or RAR before attaching. Larger attachments can take a few minutes to transfer depending on your local internet speed 🙂

Factory display