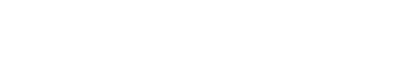

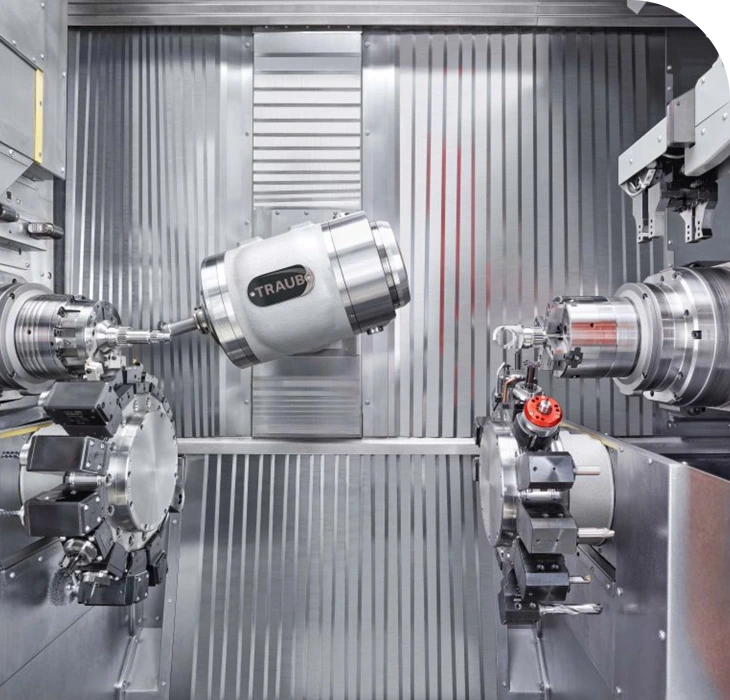

What is a milling and turning machine tool?

A mill-turning machine tool is a hybrid CNC machine tool that integrates milling (tool rotation) and turning (workpiece rotation) functions into a single, fast, powerful, and flexible machine. It can complete complex machining operations faster and more accurately than traditional machining techniques. While other machine tools can only perform a single function at a time, a mill-turning machine tool can complete up to four machining operations simultaneously.

Common configurations for machining parts on milling and turning centers

To effectively handle, operate, and machine parts throughout the manufacturing process, you must first understand the numerous parameters and configuration options available on current mill-turn machining centers. Here are some of the settings options:

Vertical:

The spindle of a vertical CNC turning-milling machine is

horizontally oriented, and workpieces are held vertically. In this setup, the cutting tools are

oriented in the same direction as the holder. Vertical CNC turning-milling centers are stronger

and more stable than horizontal counterparts due to gravity.

This design is very effective when cutting large and heavy workpieces since gravity helps to

seat these huge items into the holding solidly.

Horizontal:

This is the most popular configuration in many CNC turning

centers. However, it is less prevalent in CNC turning-milling machines. The spindle of the CNC

mill-turn machine is horizontal in this case, and workpieces are thus held horizontally. The

cutting tools have fallen out of the holder’s side.

This design is weaker than the vertical configuration because gravity does not help secure the

holding workpiece. As a result, it is rarely utilized for large, heavy workpieces.

Why use a CNC milling and turning machine tool?

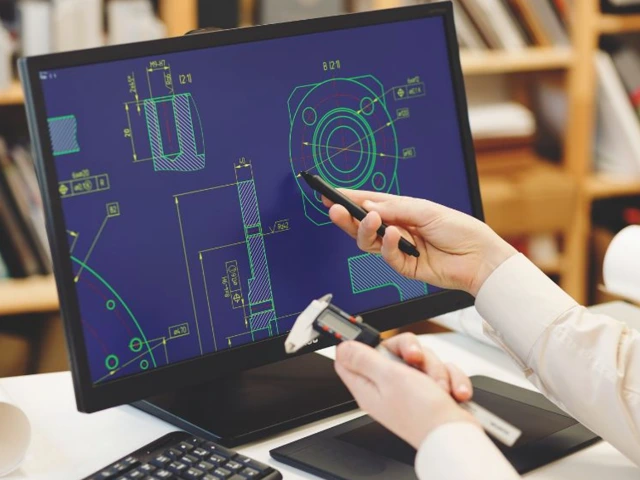

A CNC milling-turning machine tool is a computer-controlled precision machining tool used to manufacture

precision parts. Operated by a trained operator who inputs a program into the machine instructs it on

how to process the workpiece. CNC milling-turning machines achieve high precision and repeatability,

making them indispensable tools for manufacturers. Furthermore, they can machine parts with complex

geometries that are difficult or impossible to produce using traditional methods. Therefore,

milling-turning machines have become essential tools for many manufacturers.

Compared to traditional machine tools, CNC milling-turning machines offer numerous advantages. First,

they can be programmed to perform various tasks, meaning they can be used for a wide range of projects.

Second, CNC machines offer high precision, ensuring consistent machining results. Finally, CNC machines

are relatively fast, improving workshop productivity. Therefore, for any enterprise relying on precision

manufacturing, a CNC turning center or CNC milling center is an indispensable piece of equipment.

Our advantages in mill-turn machining

Get a Quote

Please place file(s) for transfer in the same folder and ZIP or RAR before attaching. Larger attachments can take a few minutes to transfer depending on your local internet speed 🙂

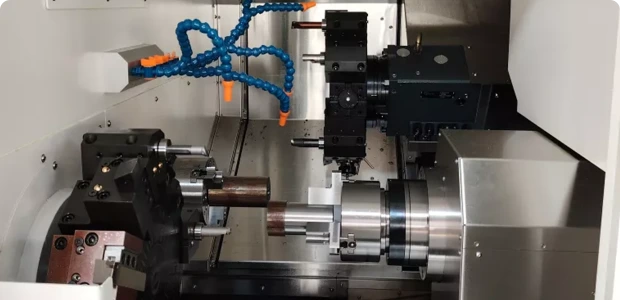

Factory display