What is five-axis CNC machining?

Five-axis CNC machining is a manufacturing process that uses Computer Numerical Control (CNC) technology to allow a tool or workpiece to move simultaneously along five different axes. In addition to the standard three linear axes—X, Y, and Z—it includes two rotary axes, allowing the tool to tilt and rotate. This means the tool can approach the workpiece from virtually any direction. This makes it possible to machine complex shapes, deep cavities, and intricate features in a single setup. Therefore, five-axis machining reduces the number of setups required, shortens machining time, improves surface finish, and increases part accuracy. It is particularly important in industries with extremely high precision and efficiency requirements, such as aerospace, automotive, and medical device manufacturing.

Our five-axis CNC machining services

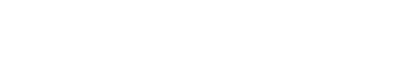

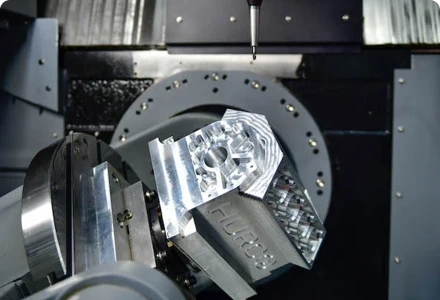

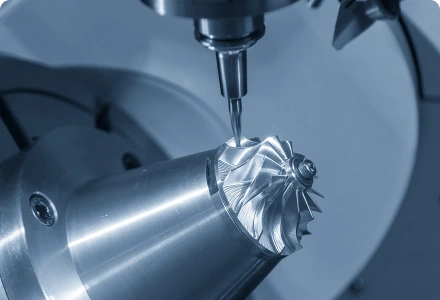

Five-axis CNC milling

Our five-axis CNC milling service focuses on tackling the challenges of machining complex geometries with ultra-high precision. Leveraging the core advantages of five-axis linkage technology, we can significantly reduce the number of part clamping operations, consistently achieving stringent tolerance standards in both prototyping and mass production scenarios. Simultaneously, we impart exceptional surface finishes to parts, ensuring a balance between machining quality and production efficiency for precision components.

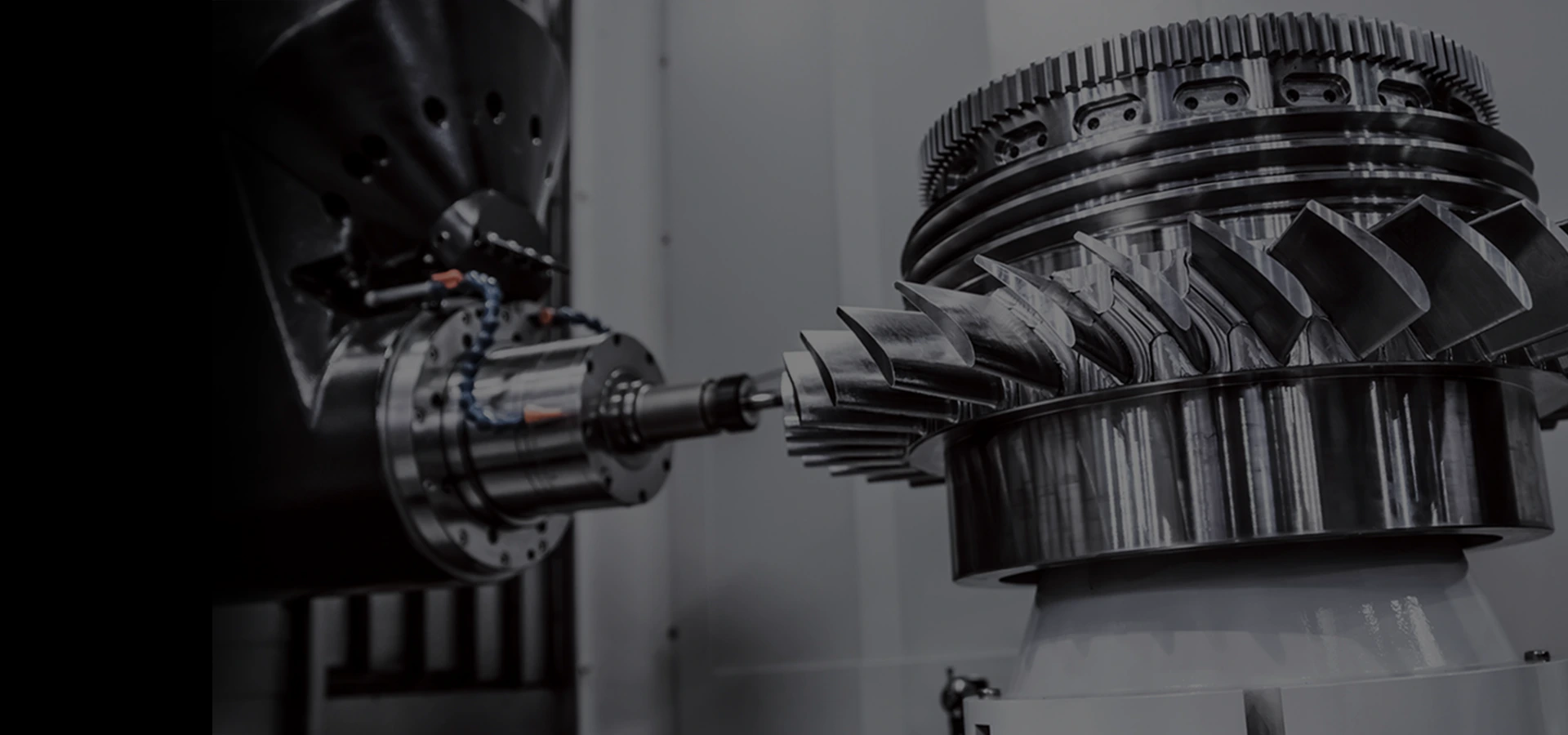

Five-axis CNC turning

For manufacturing complex cylindrical parts, our five-axis CNC turning service offers exceptional machining flexibility. With multi-angle simultaneous machining capabilities, it enables precise engraving of fine features, accurate chamfering, and stringent control of dimensional tolerances, providing high-quality machining solutions for cylindrical parts with extremely high precision requirements.

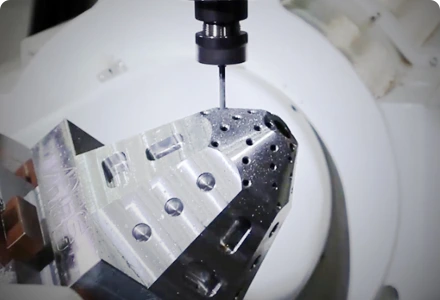

Five-axis drilling and tapping

Five-axis CNC drilling and tapping services can flexibly adapt to hole machining and tapping needs of various angles and directions within space. Through integrated precision positioning technology, multiple clamping and adjustment are eliminated, significantly improving the machining efficiency of parts with complex hole shapes,inclined hole positions and other special structures, while ensuring hole accuracy and thread machining quality.

Why use five-axis machining?

Five-axis machining offers significant advantages over traditional three-axis machining, delivering

greater flexibility, precision, and efficiency. Its core advantage lies in the fact that the cutting

tool can complete multi-faceted machining of parts without manual repositioning, reducing the number of

setups and minimizing the risk of human error. This ultimately leads to shorter production cycles and

more consistent machining results.

Using shorter, more robust cutting tools not only improves part surface quality but also extends tool

life. For parts with complex geometries, precise chamfering, and stringent tolerance requirements,

five-axis machining can achieve machining results that are difficult or even impossible to achieve using

other methods. Furthermore, it helps manufacturers enhance their market competitiveness, enabling them

to undertake more challenging projects while reducing fixture investment and rework costs, and

delivering high-quality parts quickly and accurately.

Our advantages in five-axis CNC machining

Five-axis CNC machining tolerances

Our 5-axis CNC machining capabilities include high-precision machining with tolerances up to ±0.005 mm, ensuring your parts meet the most stringent requirements.

HLH Industry can manufacture and inspect parts with tight tolerances according to your drawings and specifications, including parts with tolerances less than +/- 0.005mm.

0.5mm

CNC milling: 4000 x 1500 x 600 mm; CNC turning: 200 x 500 mm.

CNC milling: 5X5X5mm; CNC turning: 2X2mm.

Prototype production: 1-100 pieces; Small batch: 101-10,000 pieces; Large batch: 10,001 pieces or more.

3 business days.

Get a Quote

Please place file(s) for transfer in the same folder and ZIP or RAR before attaching. Larger attachments can take a few minutes to transfer depending on your local internet speed 🙂

Factory display