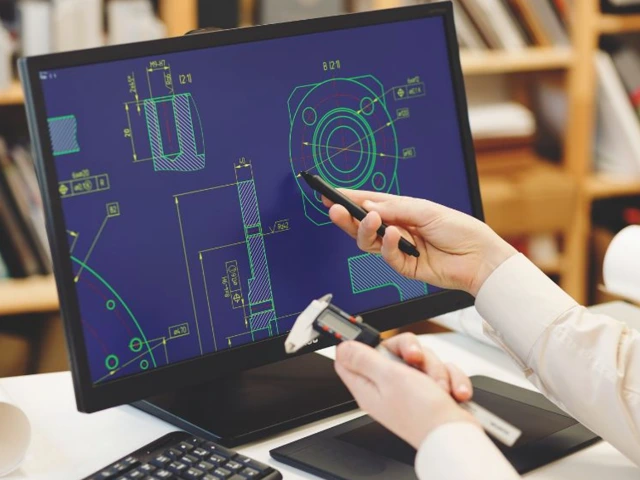

What is CNC turning?

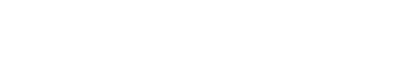

CNC turning is a versatile and high-precision machining process used to

manufacture high-precision mechanical parts. It is ideally suited for cutting the inner and outer

cylindrical surfaces of shafts and discs, as well as machining inner and outer conical surfaces at

various angles. This process is particularly well-suited for cutting the inner and outer cylindrical

surfaces of shafts and discs, while also accurately machining inner and outer conical surfaces at

various angles.

Leveraging advanced CNC lathe equipment and a highly experienced technical team, we can achieve

high-quality machining of complex turned parts – not only strictly controlling tolerance standards but

also giving the parts exceptional surface finish and machining accuracy. Whether you need prototype

sample production or mass production of parts, we possess the professional technical capabilities and

extensive experience to efficiently and reliably meet your various specification requirements.

Our CNC turning services

We are equipped with high-quality milling cutters that support 3-axis, 4-axis, and 5-axis milling, enabling us to bring your designs to life quickly and accurately. Regardless of your industry, we can provide instant pricing, free DFM (Design for Manufacturability) feedback, and on-demand manufacturing for your custom CNC milled parts.

Precision turning

Our precision turning service is dedicated to ensuring that every part precisely meets pre-set specifications. Leveraging advanced CNC lathes, we achieve stringent tolerance control and high-precision machining results for both simple basic parts and complex precision components.

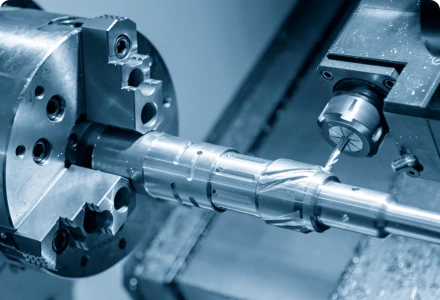

Manufacturing of complex parts

Focusing on the manufacturing needs of turning parts requiring precision machining and complex geometries, our experienced technical team possesses exceptional project-solving capabilities. Faced with various challenging machining tasks, the team consistently delivers high-quality results, ensuring that every delivery meets expectations.

Small batch production

Our CNC turning services offer significant advantages in small-batch production scenarios, precisely matching your manufacturing needs with flexible and efficient machining modes. Regardless of order size, we adhere to consistent quality control standards to ensure the consistency of quality for all delivered products.

CNC turning tolerances

Our CNC turning capabilities include high-precision machining with tolerances up to ±0.005mm, ensuring your parts meet the most stringent requirements.

HLH Industry can manufacture and inspect parts with tight tolerances according to your drawings and specifications, including parts with tolerances less than +/- 0.005mm.

0.5mm

0.020 inches (0.50 millimeters). Specific dimensions may vary depending on part geometry and the material selected.

5X5X5mm

HLH Industry can process any standard thread size, and we can also process custom threads.

By default, sharp edges are ground down and burrs are removed.

The standard surface treatment is machined to its original state: surface roughness Ra≥125. Other surface treatment options can be specified upon request.

Our advantages in CNC turning

Get a Quote

Please place file(s) for transfer in the same folder and ZIP or RAR before attaching. Larger attachments can take a few minutes to transfer depending on your local internet speed 🙂

Factory display