What is CNC milling?

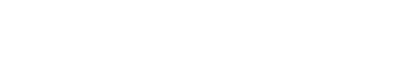

CNC milling is a precision machining process that uses computer-controlled

cutting tools (such as milling cutters) to remove material from a workpiece, thereby creating complex

designs and parts. We specialize in custom CNC milling services, achieving machining accuracy up to

±0.005mm. Our advanced equipment, including precision CNC milling machines and five-axis machining

centers, enables us to handle complex geometries and a wide variety of materials, such as aluminum,

stainless steel, and plastics.

CNC milling is suitable for machining workpieces of various structures and shapes. It can efficiently

complete machining tasks such as rounding, faceting, curvature, serration, tapping, drilling, boring,

reaming, milling planes, milling bevels, cams, and curved surface contours. As a fully equipped CNC

milling parts factory, we ensure superior quality, efficient production, and timely delivery to meet the

precise specifications and needs of customers in multiple industries, including aerospace, automotive,

and medical device.

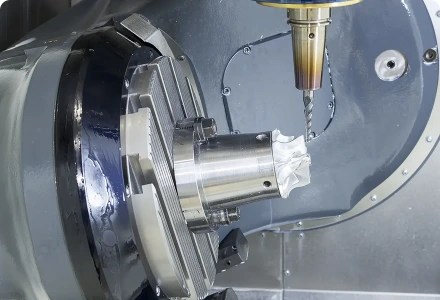

Our CNC milling services

We are equipped with high-quality milling cutters that support 3-axis, 4-axis, and 5-axis milling, enabling us to bring your designs to life quickly and accurately. Regardless of your industry, we can provide instant pricing, free DFM (Design for Manufacturability) feedback, and on-demand manufacturing for your custom CNC milled parts.

Three-axis CNC milling

In 3-axis milling, a rotary tool can translate relative to the workpiece along the X, Y, and Z axes. This process is cost-effective while meeting accuracy requirements, making it ideal for machining parts with planar geometry or simple curves.

Four-axis CNC milling

This process introduces an additional axis of rotation (usually the A-axis), allowing for relatively complex geometries and suitable for parts that require machining on multiple sides without repositioning.

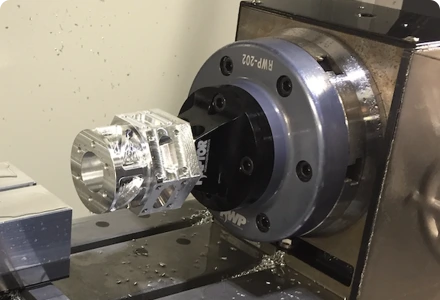

Five-axis CNC milling

Five-axis milling machines add two rotary axes (usually the A-axis and the B-axis) to the three linear axes (X, Y, Z), enabling the machining of highly complex 3D shapes with extremely high precision and efficiency.

CNC milling tolerances

Our CNC turning capabilities include high-precision machining with tolerances up to ±0.005mm, ensuring your parts meet the most stringent requirements.

HLH Industry can manufacture and inspect parts with tight tolerances according to your drawings and specifications, including parts with tolerances less than +/- 0.005mm.

0.5mm

4000 x 1500 x 600 mm

5X5X5mm

Prototype production: 1-100 pieces; Small batch: 101-10,000 pieces; Large batch: 10,001 pieces or more.

3 business days.

Our advantages in CNC milling

Get a Quote

Please place file(s) for transfer in the same folder and ZIP or RAR before attaching. Larger attachments can take a few minutes to transfer depending on your local internet speed 🙂

Factory display