Precision processing capability of industrial machinery

We offer tailor-made high-quality manufacturing solutions for the industrial equipment industry. With advanced

technologies and a team of experienced professionals, we can deliver precise parts and components that meet the

stringent requirements of industrial applications. From prototype production to mass production, we are

committed to providing efficient and outstanding support for your projects.

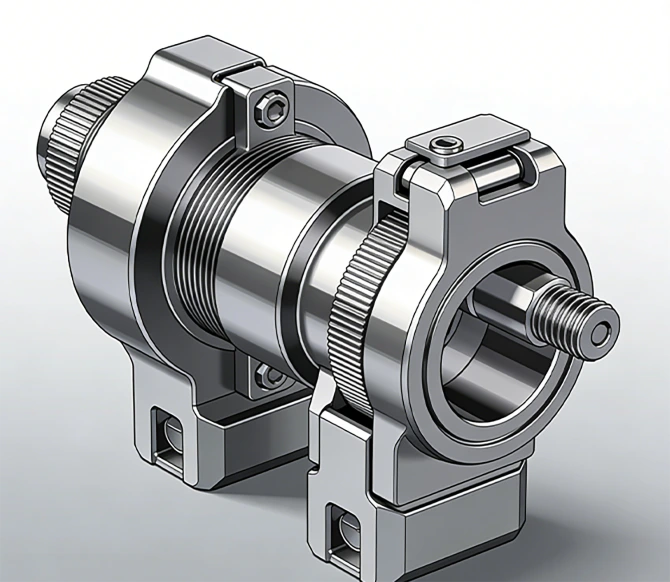

We provide a wide range of precision castings and machining parts for the industry leaders in the global

construction machinery end market. These complex components include:

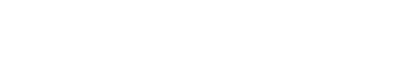

and valve body

Advantages and Features

Our industrial machinery industry solutions boast a number of key advantages and unique features, enabling us to stand out from our competitors.

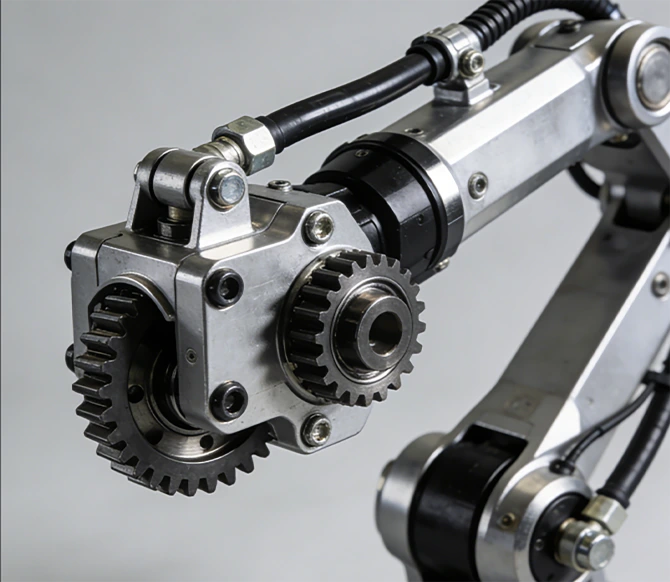

Ultra-high precision standard

Relying on advanced manufacturing technology, we lay a solid foundation of high-precision quality for each part. We can stably achieve a strict tolerance control of ±0.005 millimeters, ensuring that all parts fully meet the design specifications and quality requirements, and precisely match the performance demands of high-end application scenarios.

Fast delivery turnaround

Focusing on meeting the customers’ urgent delivery deadlines, we have established an efficient production system. While strictly adhering to the quality standards, we achieve rapid production turnover. Through streamlined and optimized processing procedures, 98% of the orders can be delivered within the agreed time or even ahead of schedule, helping customers shorten the product launch cycle and, on average, improving the launch efficiency by 15%, thereby establishing a competitive advantage in the market.

Comprehensive material adaptation

To meet the specific requirements of industrial machinery, we offer a wide range of material options covering metals, plastics, composite materials, etc. All materials have been rigorously selected to ensure that the components fully meet the professional standards of the industrial machinery industry in terms of performance stability and durability, and are suitable for various complex application scenarios.

Full-time expert support

From the initial product design stage to the final production implementation, our experienced team will provide professional technical guidance throughout the process. The core engineering team has over 20 years of industry expertise. With profound technical accumulation, they offer precise suggestions and quality guarantees to customers, ensuring that every project achieves high-quality results.

Case study

Our industrial equipment manufacturing services have been successfully applied in several high-impact projects. The following cases demonstrate our ability to provide high-quality and high-precision components to meet the specific requirements of the industrial equipment industry.

Project Background: : A leading heavy machinery manufacturer needs to produce high-precision parts for its new series of excavators.

Challenge: : To manufacture parts that can maintain strict tolerances and durability under extreme conditions.

Solution: : We employ high-strength steel alloys to offer precise CNC machining services, with tolerances as low as 0.005mm.

Result: : These components meet all the performance requirements, resulting in a 15% increase in mechanical efficiency and reliability.